MAXOS

SHANMAN ENINEERING Sdn Bhd is proud to announce that we have been given the task and responsibility to assist in Sales and Marketing and together with technical support on behalf of AUER Lighting Gmbh for their range of MAXOS Safety Sight and Level Gauge Glasses Special-tempered Made in Germany. Shanman will also use Maxos Products for their level gauge housings produced. Primarily Shanman Will cover S E Asia and Oceania Markets along with neighboring countries. Please get in touch with us for your requirements.

The complete safety sight and

level gauge glass program

MAXOS® safety sight and level gauge glasses have proved themselves universally where visual process control is essential. This includes pressure vessels subjected to thermal and chemical loads and liquid level gauge applications.

A high safety level is secured through the use of special borosilicate glass of high chemical durability, exceptional purity and homogeneity. The low thermal expansion of our SUPRAX® 8488 borosilicate glass, combined with thermal prestressing (tempering) creates a high resistance to sudden temperature changes.

The material properties values and tight dimensional tolerances are guaranteedby production and quality controls. With these exceptional safety characteristics, MAXOS® safety sight and level gauge glasses can be used under extreme operational conditions. It is therefore mainly these safety aspects which influence responsible technicians again and again to choose MAXOS®.

MAXOS® product range

Special tempered reflex and transparent level gauge glasses and disc

sight glasses can be supplied in accordance to:

• DIN 7080/7081

• BS 3463

• JIS B 8211

• MIL – G – 16356 D

• Auer USA specification

• H igh pressure

• C ustomer specification

• Aluminosilicate glass on request

Glass type SUPR AX® 8488

| Coefficient of expansion α 20 °C/300 °C | 4.3 x 10–6 K–1 |

|---|---|

| Transformation temperature | 540 °C |

| Glass temperature for the viscosities dPas (Poise) | 1013.0 560 °C 107.6 800 °C 104.0 1200 °C |

| Density at 25 °C | 2.3 g/cm3 |

| Modulus of elasticity | 67 x 103 N/mm2 |

| Poisson‘s ratio μ | 0.20 |

| Thermal conductivity λ at 90 °C | 1.2 W/ M-K |

| Refractive index nd (λ = 587.6 nm) | 1.484 |

| Photoelastic parameter K | 3.2 x 10–6 mm2/N |

| Chemical characteristics |

Hydrolytic resistance |

Acid resistance |

Alkali resistance |

|---|---|---|---|

| Test acc. to | DIN ISO 719 | DIN ISO 1776 | DIN ISO 695 |

| max. abrasion acc. to DIN ISO |

0.1 | <100 μg Na2O each 100 cm2 |

>75–175 mg each 100 cm2 |

| MAXOS® max. abrasion |

0.050 | <60 μg Na2O each 100 cm2 |

<100 mg each 100 cm2 |

| MAXOS® | HGB 1 | – | class A2 |

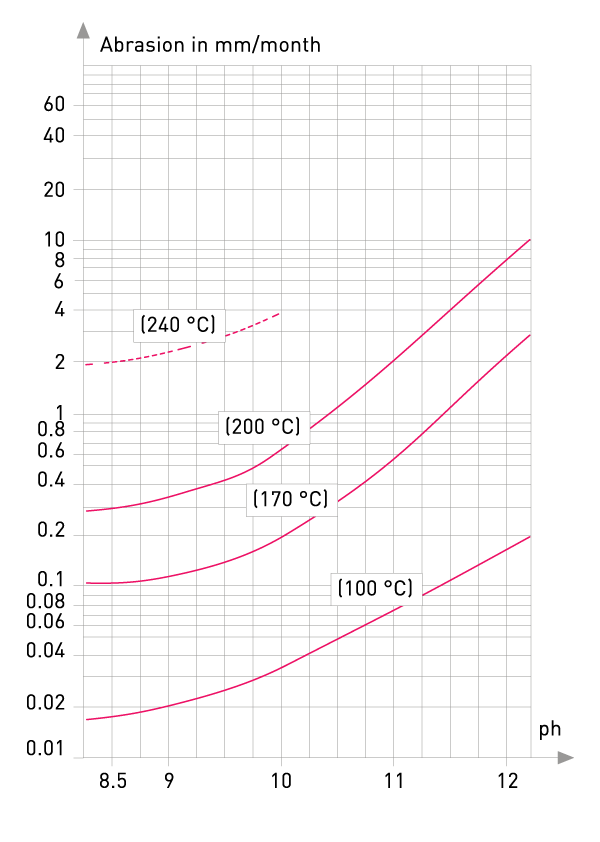

The abrasion of MAXOS® glass in watery phase for

several temperatures as a function of the ph-value.

MAXOS® – a registered trademark of Auer Lighting GmbH

SUPRAX® – a registered trademark of SCHOTT AG

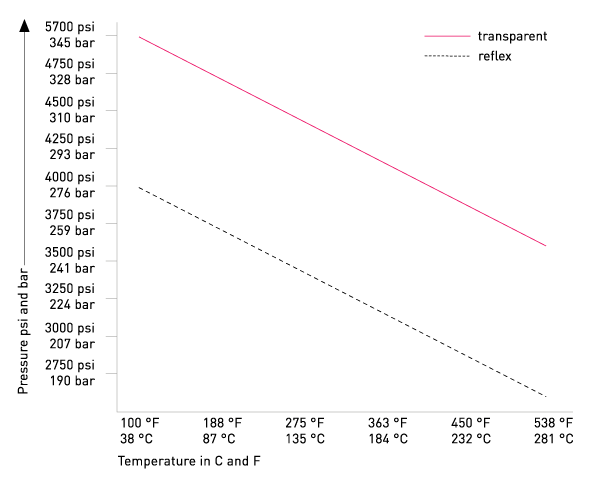

MAXOS ® Level Gauge Glasses

Long form reflex and transparent

Bending strength is determined by the surface compressive stress and the

inherent resistance of the glass. The inherent resistance is heavily dependent

upon the surface quality.

For safety reasons, the stress to the glasses caused by internal forces, thermal stress and vessel pressure have to be totally absorbed by the surface compressive stress so that a tensile stress of the glass surface is prevented.

Bending strength (typical values)

| Standard level gauge glasses ≥ 150 N/mm2 21,000 psi Average 170 N/mm2 25,000 psi |

High pressure level gauge glasses ≥ 180 N/mm2 26,000 psi Average 200 N/mm2 29,000 psi |

|---|

Temperature

Thermal shock resistance Δ T 265 K

Max. permissible temperature 300 °C (572 °F)

Protected with mica 320 °C (608 °F)

| Application conditions | Maximum permissible pressure | Maximum permissible temperature |

||

|---|---|---|---|---|

| bar | psi | °C | °F | |

| Saturated steam or hot water in direct contact with reflex or transparent sight glasses | 35 | 500 | 243 | 470 |

| Saturated steam or hot water in contact with transparent sight glasses protected with mica | 103 | 1,500 | 320 | 608 |

| Non-corrosive, non-steam service and no technically significant glass attack, with reflex or transparent glasses | 280 | 4,000 | 320 | 608 |

| Transparent sight glasses in contact with medias with no technically significant glass attack | 345 | 5,000 | 38 | 100 |

| High pressure transparent sight glasses in special armatures (gauges) | 414 | 6,000 | 38 | 100 |

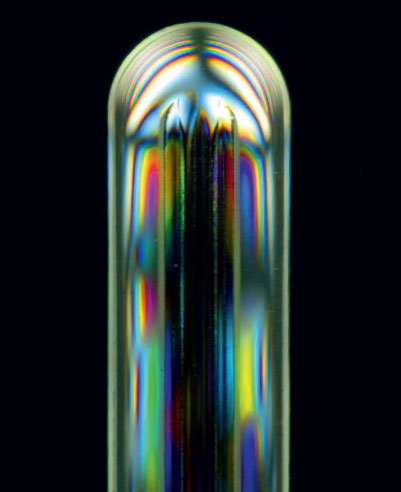

Special tempered MAXOS® glass under polarized light.

MAXOS ® Disc Sight Glasses

Technical charateristics

| Bending strength | ≥ 160 N/mm2 | 23,000 psi |

|---|---|---|

| Surface compressive stress | ≥ 100–140 N/mm2 | 14,500–20,000 psi |

| Parallelism | ≤ 0.20 mm | 0.008 inches |

| Flatness*) | Diameter: | up to 100 mm ≤ 0.05 above 100 up to 150 mm ≤ 0.08 above 150 up to 200 ≤ 0.12 above 200 mm ≤ 0.15 |

| Thermal shock resistance Δ T | 265 K | |

| Max. permissible temperature | 300 °C | 572 °F |

| Protected with mica | 320 °C | 608 °F |

*) Measurements of flatness are taken only in the sealing area.

Dimensional tolerances

(DIN 7080)

Diameter

up to 135 mm ± 0.5 mm

150 to 200 mm ± 0.8 mm

above 200 mm ± 1.0 mm

Thickness

up to 20 mm + 0.50 mm / – 0.25 mm

above 20 mm + 0.80 mm / – 0.40 mm

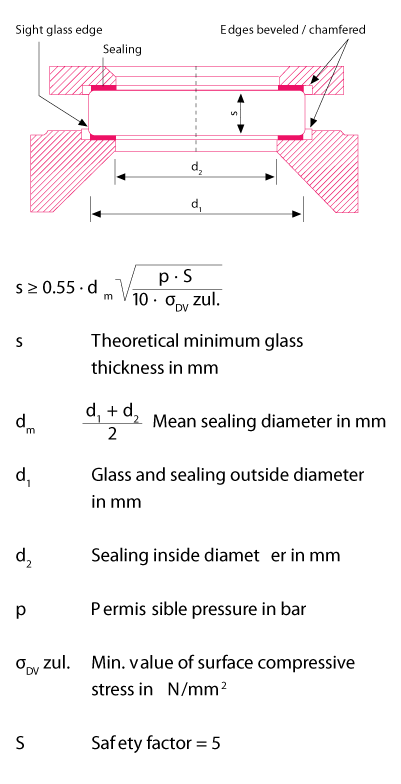

Calculation of the glass thickness

All MAXOS® glasses are marked with a

production code number.

Available sizes

Special dimensional design on request, e.g. Ø min. 30 – max. 265 mm

and thickness min. 10 – max. 30 mm.

| Dimensions d1 x s (mm) |

Inspection aperture d2 (mm) |

Permissible pressure in bar |

Dimensions d1 x s (inch) |

Inspection aperture d2 (inch) |

Permissible pressure in psi |

|---|---|---|---|---|---|

| 30 x 15 | 20 | 200 | 1.181 x 0.591 | 0.787 | 2900 |

| 31.6 x 12.75 | 20 | 150 | 1.244 x 0.502 | 0.787 | 2175 |

| 34 x 17 | 24 | 200 | 1.339 x 0.669 | 0.945 | 2900 |

| 35 x 7 | 25 | 25 | 1.378 x 0.276 | 0.984 | 363 |

| 40 x 10 | 30 | 40 | 1.575 x 0.394 | 1.181 | 580 |

| 40 x 12 | 30 | 50 | 1.575 x 0.472 | 1.181 | 725 |

| 45 x 10 | 32 | 40 | 1.772 x 0.394 | 1.260 | 580 |

| 45 x 12 | 32 | 50 | 1.772 x 0.472 | 1.260 | 725 |

| 50 x 10 | 35 | 25 | 1.969 x 0.394 | 1.378 | 363 |

| 50 x 12 | 35 | 40 | 1.969 x 0.472 | 1.378 | 580 |

| 55 x 10 | 40 | 25 | 2.165 x 0.394 | 1.575 | 363 |

| 60 x 10 | 45 | 16 | 2.362 x 0.394 | 1.772 | 232 |

| 60 x 12 | 45 | 25 | 2.362 x 0.472 | 1.772 | 363 |

| 60 x 15 | 45 | 40 | $2.362 x 0.591 | 1.772 | 580 |

| 60 x 20 | 45 | 95 | 2.362 x 0.787 | 1.772 | 1377 |

| 63 x 8 | 48 | 8 | 2.480 x 0.315 | 1.890 | 116 |

| 63 x 10 | 48 | 16 | 2.480 x 0.394 | 1.890 | 232 |

| 63 x 12 | 48 | 25 | 2.480 x 0.472 | 1.890 | 363 |

| 63 x 15 | 48 | 40 | 2.480 x 0.591 | 1.890 | 580 |

| 65 x 10 | 50 | 12 | 2.559 x 0.394 | 1.969 | 174 |

| 65 x 15 | 50 | 40 | 2.559 x 0.591 | 1.969 | 580 |

| 70 x 12 | 55 | 16 | 2.756 x 0.472 | 2.165 | 232 |

| 70 x 15 | 55 | 25 | 2.756 x 0.591 | 2.165 | 363 |

| 75 x 12 | 60 | 16 | 2.953 x 0.472 | 2.362 | 232 |

| 80 x 10 | 65 | 10 | 3.150 x 0.394 | 2.559 | 145 |

| 80 x 12 | 65 | 16 | 3.150 x 0.472 | 2.559 | 232 |

| 80 x 15 | 65 | 25 | 3.150 x 0.591 | 2.559 | 363 |

| 80 x 20 | 65 | 40 | 3.150 x 0.787 | 2.559 | 580 |

| 90 x 10 | 70 | 8 | 3.543 x 0.394 | 2.756 | 116 |

| 92 x 10 | 72 | 8 | 3.622 x 0.394 | 2.835 | 116 |

| 95 x 10 | 75 | 6 | 3.740 x 0.394 | 2.953 | 87 |

| 95 x 15 | 75 | 16 | 3.740 x 0.591 | 2.953 | 232 |

| 100 x 10 | 80 | 7 | 3.937 x 0.394 | 3.150 | 101 |

| 100 x 12 | 80 | 10 | 3.937 x 0.472 | 3.150 | 145 |

| 100 x 15 | 80 | 16 | 3.937 x 0.591 | 3.150 | 232 |

| 100 x 20 | 80 | 25 | 3.937 x 0.787 | 3.150 | 363 |

| 100 x 25 | 80 | 40 | 3.937 x 0.984 | 3.150 | 580 |

| 110 x 12.5 | 85 | 10 | 4.331 x 0.492 | 3.346 | 145 |

| 113 x 15 | 88 | 10 | 4.449 x 0.591 | 3.465 | 145 |

| 115 x 15 | 90 | 10 | 4.528 x 0.591 | 3.543 | 145 |

| 120 x 15 | 95 | 10 | 4.724 x 0.591 | 3.740 | 145 |

| 125 x 15 | 100 | 10 | 4.921 x 0.591 | 3.937 | 145 |

| 125 x 20 | 100 | 16 | 4.921 x 0.787 | 3.937 | 232 |

| 125 x 25 | 100 | 25 | 4.921 x 0.984 | 3.937 | 363 |

| 125 x 30 | 100 | 40 | 4.921 x 1.181 | 3.937 | 580 |

| 130 x 15 | 105 | 10 | 5.118 x 0.591 | 4.134 | 145 |

| 135 x 25 | 110 | 25 | 5.315 x 0.984 | 4.331 | 363 |

| 150 x 10 | 125 | 2 | 5.906 x 0.394 | 4.921 | 29 |

| 150 x 15 | 125 | 8 | 5.906 x 0.591 | 4.921 | 116 |

| 150 x 20 | 125 | 10 | 5.906 x 0.787 | 4.921 | 145 |

| 150 x 25 | 125 | 16 | 5.906 x 0.984 | 4.921 | 232 |

| 150 x 30 | 125 | 25 | 5.906 x 1.181 | 4.921 | 363 |

| 175 x 20 | 150 | 10 | 6.890 x 0.787 | 5.906 | 145 |

| 175 x 25 | 150 | 16 | 6.890 x 0.984 | 5.906 | 232 |

| 175 x 30 | 150 | 25 | 6.890 x 1.181 | 5.906 | 363 |

| 200 x 20 | 175 | 8 | 7.874 x 0.787 | 6.890 | 116 |

| 200 x 25 | 175 | 10 | 7.874 x 0.984 | 6.890 | 145 |

| 200 x 30 | 175 | 16 | 7.874 x 1.181 | 6.890 | 232 |

| 250 x 20 | 225 | 4 | 9.843 x 0.787 | 8.858 | 58 |

| 250 x 25 | 225 | 8 | 9.843 x 0.984 | 8.858 | 116 |

| 250 x 30 | 225 | 10 | 9.843 x 1.181 | 8.858 | 145 |

| 265 x 30 | 240 | 8 | 10.433 x 1.181 | 9.449 | 116 |